-40%

US 26in Semi-Auto Small Home Cold Laminator for Business Card Laminating Machine

$ 368.17

- Description

- Size Guide

Description

DescriptionQOMOLANGMA 26 in Semi

-

Auto Small Home Cold Laminator, for

Business Card Laminating

2years warranty ! Door to Door service

Professional Team, 24h Technical Sup

port by Email or Callin

g!

Quality Report:

Ving 26 in Semi - Auto Small Home Electric Business Card Cold Laminator

Same function like enduraLAM Desktop 24 in Cold Laminator

Cold laminator ideal for providing abrasion and added UV resistance to solvent inkjet prints

Semi - auto cold laminating machine (Automatic take - up rolls of back paper), with functions of single sided cold laminating and mounting by electric Table Top Model, driven by electric or by hand (For option)

No need to heat, with auto rewind shafts

Cold laminators are the most cost-effective machines for solvent and eco-solvent printers. Hot laminators are not recommended for solvent and eco-solvent prints as the heat degrades the print quality. These laminators use pressure sensitive (cold) films, to protect the color balance of a digital print.

Mounting or laminating a digital print will protect the print, extend its life and improve customer satisfaction. Customer satisfaction means that the customer will return to your shop for another job. Both you and your customer win when you offer print finishing services.

The foot switch allows greater control and accuracy when feeding long and wide prints.

Two EPDM hard rubber rollers resist tearing, and solvents. Adjustable roll crank on side adjusts thickness, up to 3/4 inch. Tension clutches are placed outside the unit for easy adjustments.

All controls are placed for easy reach, including emergency shut off switch. Controls include: master on/off, variable speed dial, forward/reverse switch, foot pedal feed system.

26"Semi - auto Small Home Electric Business Card Cold Laminating Machine

Model

FMJ-650-II-PLUS

Maximum Laminating Width

650mm (26")

Maximum Laminating Thickness

10mm (0.4")

Laminating Speed

0 - 3m (118") / min

Forward / Reverse

Yes

Foot Pedal

Yes

Roller’s Diameter

65mm (2.6")

Auto rewind liner pickup

Yes

After Laminating Pickup

No

Emergency Stops

Yes

Safety Photocell

No

Media Core Size

1"

Power Supply

AC 110V / 220V, 50Hz or 60Hz

Good color reducibility and light transmittance, free of bubbles and snowflake point!

A perfect fit for entry level customer, who is looking for an affordable and professional cold laminator for their projects.

This new model can be widely used for pre-masking vinyl graphic, mount prints on substrate, over laminating inkjet prints and so on.

Easy to use and Guarantee a quality result each time.

FMJ-650-II-PLUS-US is upgraded from FMJ-650-II, it has all functional characteristics of FMJ-650-II, and comes with support shaft for manually rewinding the backing paper in some projects.

Features

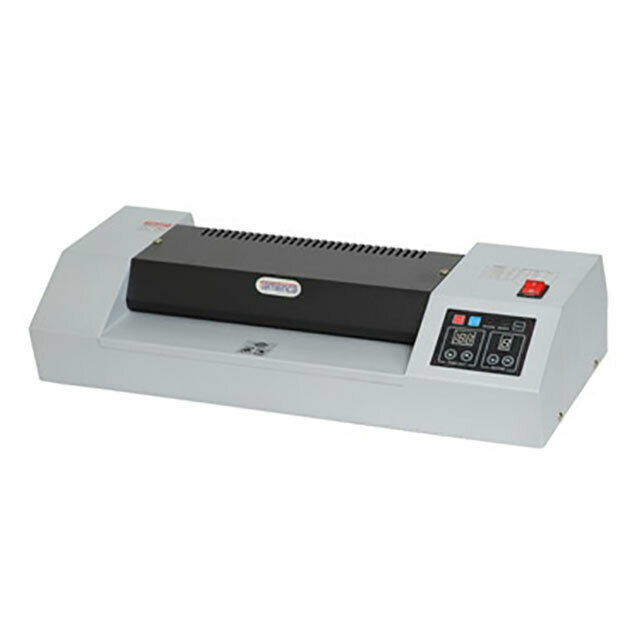

• The mounting master 26" is motorized table top laminators. Simple structure, portable machine;

• This cold laminator comes with foot pedal with forward and reverse control to free your both hands from handling the work being processed;

• The easy speed control makes your daily job more handily; laminating speed can be easily adjusted from 0-3m (118") / min;

• This model is designed for mounting and laminating inkjet prints, but is equally capable of handling photographic or any printed media;

• 1" core auto - grip rollers for easy laminating film setup;

• 65mm (2.6") bigger rollers for best quality laminating control;

• This cold laminatorhas simple structure, reasonable, humane and low cost characteristics;

• This cold laminator is operated conveniently. Applying application tapes, applying double side adhesives and vinyl.

Details

High quality

Butadiene acrylonitrile rubber roller, 65mm (2.6 inch diameter)Generally speaking, the lifespan of a roller is about 4-5 years or longer. The roller is the key component of a laminator and it directly affects the quality of lamination, so it is crucial to give good care and maintenance to the roller.

Working table with ruler, this machine’s table is very even. The feed table is more stable, and the laminating effective is better.

Note:

When you assemble this laminator, make sure you have an extra core (empty vinyl roll core would work) to use for rolling up the backing from the laminate.

25" Laminator instructions for setup:

1. Use attached Graphic as a reference for setting up the laminator.

2. While standing at the front of the machine you will need to place blank cardboard curve (media core) on the top roller for the take-up of the laminate backing. Tape the backing paper to the core.

3. On the right side of the machine install the green band (may be diff. color) onto the slotted steel wheels put one twist in the band to make an 8 shape.

4. Place Roll of Laminate on back roller when roll has gloss side on the outside feed the roll from back/under then go under the chrome tension bar.

5. Separate the laminate from the backing paper. Tape the backing paper to the blank cardboard core and hand turn the roll a few times. The laminate needs to be sticky side out going over the top roller and eventually between both orange rollers when running a job through. When the machine is not in use it would be a good idea to have a scrap piece of paper or something to keep the laminate from going around the bottom pressure roller.

6. The two large adjustments wheels on both sides of the machine is for the tension and level of the orange pressure roller.

7. The two Knobs that are located on the right side of the machine on the media bars are for the tension of each roll.

Helpful Tips:

If the media you are laminating is smaller than the actual laminate, use crafting paper or something similar to place under your media so it will not stick to the laminator's rubber rollers. Endura Roller Tray would be good to hold crafting paper.

Function

FMJ-650-II-PLUS-US

is semi – auto cold laminator (Automatic take - up rolls of liner paper, without take – up roller for after lamination prints).

FMJ-650-II

is common manual and electrical cold laminator, cannot take up the liner paper mechanically.

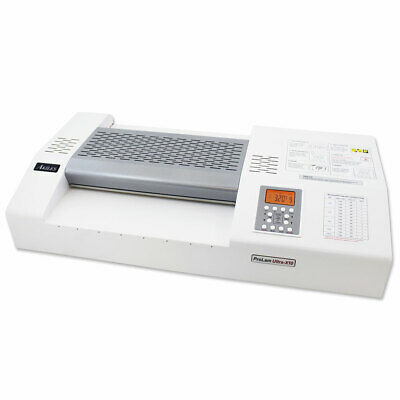

Appearance - Take reasonable money to buy the suitable machines

Our Machine:

Appearance design of FMJ-650-II-PLUS-US cold laminating machine has novel, simple and reasonable structure, humane and low cost characteristics.

The other machine:

The top right side machine’s appearance design is too thin, and it is easy to damage, and it has many questions if you buy.

Material of rollers

FMJ-650-II-PLUS-US

adopts high quality diameter 65 mm (2.6”) acrylonitrile butadiene original rubber rollers, which can control the quality laminating very well. At the between upper and lower roller the picture laminated is the straight-line movement of internal forces. It saves manpower and is easy to operate.

The common cold laminator machine

adopts recycled rubber roller, and up and down roller’s thickness is not the same that will affect the laminating effect and machine’s using life.